In today’s rapidly evolving industrial landscape, businesses are under increasing pressure to enhance operational efficiency, minimise human error, and ensure worker safety while scaling their processes.

Industrial automation software is revolutionising how factories operate, enabling smarter, safer, and more responsive manufacturing environments. As part of the broader Industry 4.0 movement, this software leverages real-time data, predictive analytics, and machine learning to optimise operations and unlock new levels of performance.

Enhancing Operational Safety Through Automation

Safety remains a critical priority in industrial operations, particularly in sectors such as oil and gas, chemical processing, mining, and manufacturing. Human error, equipment malfunctions, and hazardous environments pose continuous risks. Industrial automation software mitigates these risks by minimising manual intervention and enabling predictive maintenance, thereby reducing exposure to potentially dangerous situations.

Automation software is capable of continuously monitoring equipment conditions and system parameters, detecting anomalies well before they escalate into safety hazards. By automating shutdown procedures, emergency alerts, and safety compliance protocols, these systems help organisations proactively protect both their workforce and their assets.

Additionally, industrial automation software enforces standardised workflows and safety protocols, reducing variability in operations and ensuring consistent adherence to regulations. This standardisation is especially beneficial in multi-site or global operations where manual oversight would otherwise be difficult.

Driving Speed and Efficiency in Operations

One of the most immediate benefits of industrial automation software is the acceleration of operational processes. Whether it involves assembly lines, packaging, quality inspection, or supply chain management, automation software enables real-time decision-making and optimises machine and labour utilisation.

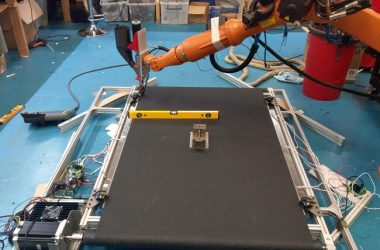

By integrating with sensors, programmable logic controllers (PLCs), and supervisory control and data acquisition (SCADA) systems, automation software enables instant feedback loops and precise control over production parameters. This agility allows manufacturers to respond quickly to changes in demand, detect inefficiencies, and implement corrective actions without significant downtime.

Factories that have implemented industrial automation software saw up to a 25% reduction in cycle time and up to a 30% increase in throughput across various production lines. These improvements are particularly critical in highly competitive sectors such as electronics, automotive, and food processing, where speed to market is a major differentiator.

Moreover, automation software supports advanced analytics and visual dashboards, enabling quick performance reviews and enhanced resource planning. This ensures faster issue resolution and continuous improvement across the production lifecycle.

Enabling Scalable Growth in the Digital Age

Scalability is another key advantage offered by industrial automation software. As enterprises grow, so does the complexity of their operations – from managing multiple production lines to coordinating distributed facilities and supply chains. Manual processes become increasingly inefficient and prone to error at scale.

Automation software provides the digital backbone needed for this expansion. Cloud-based solutions, remote access capabilities, and modular architecture allow companies to scale their operations without a proportional increase in labour or overhead costs. Automation also enables centralised control and monitoring, providing enterprise-wide visibility and standardisation across operations.

Importantly, industrial automation software supports customisation and flexibility, allowing businesses to adapt to new market conditions, product variations, and regulatory changes. This adaptability is vital in dynamic environments where change is constant, and agility is essential.

With the integration of AI and machine learning, these systems continue to evolve, offering smarter automation strategies and more accurate forecasts. This future-ready approach ensures that companies investing in automation are not only scaling efficiently but are also building resilience in their operations.

What Does the Future Hold?

In the era of Industry 4.0, the strategic use of industrial automation software is no longer a competitive advantage – it is a necessity. By enhancing safety through predictive maintenance and standardised procedures, improving speed with real-time process control, and enabling scalable growth through flexible and intelligent systems, this software is redefining what is possible in industrial operations.

Partnering with reputable and experienced automation software providers ensures access to robust, secure, and future-ready solutions tailored to specific operational needs. These trusted brands offer not only advanced technology but also the support, integration expertise, and innovation needed to drive sustainable growth in an increasingly digital industrial landscape.

As industries face increasing demands for efficiency, safety, and adaptability, those leveraging robust industrial automation solutions will be best positioned to thrive in the complex, fast-moving digital economy.